Our GLL anti-slip aluminum plate uses 5 series (such as 5052, 5083) and 6 series (such as 6061, 6063) aluminum alloy substrates to form a differentiated performance matrix. The 5 series aluminum alloy uses 2.2%-2.8% magnesium as the core alloy element, and exhibits excellent weather resistance in corrosive environments such as offshore platforms and chemical plants.

Our GLL anti-slip aluminum plate have many advantages :

Advanced Surface Engineering:

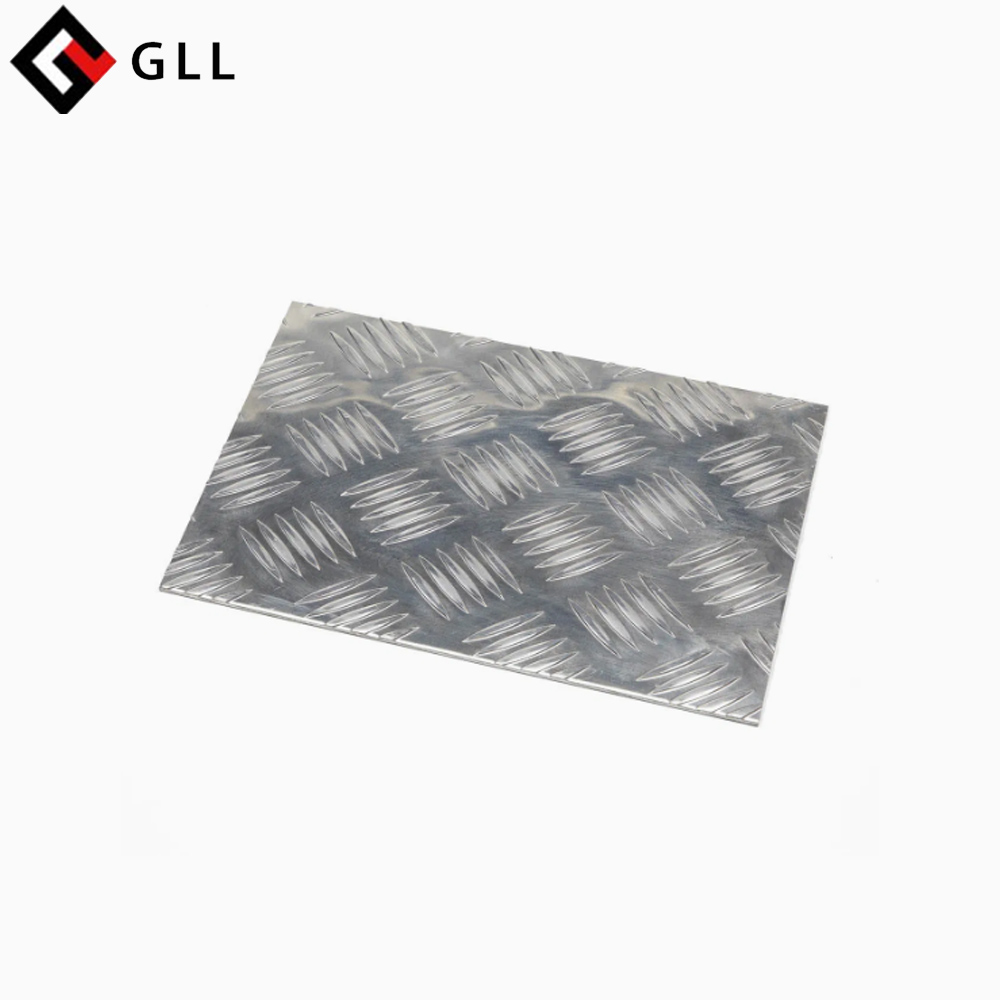

1. Dual Anti-Slip Architecture

Macro-Texture: Precision double-embossing technology creates a 5mm×5mm diamond-shaped protrusion array with strictly controlled height (0.8-1.2mm), optimizing pedestrian safety and vehicle traction.

Micro-Texture: Chemical etching generates micron-scale pit structures, forming a hierarchical surface topology that enhances friction under both dry and wet conditions.

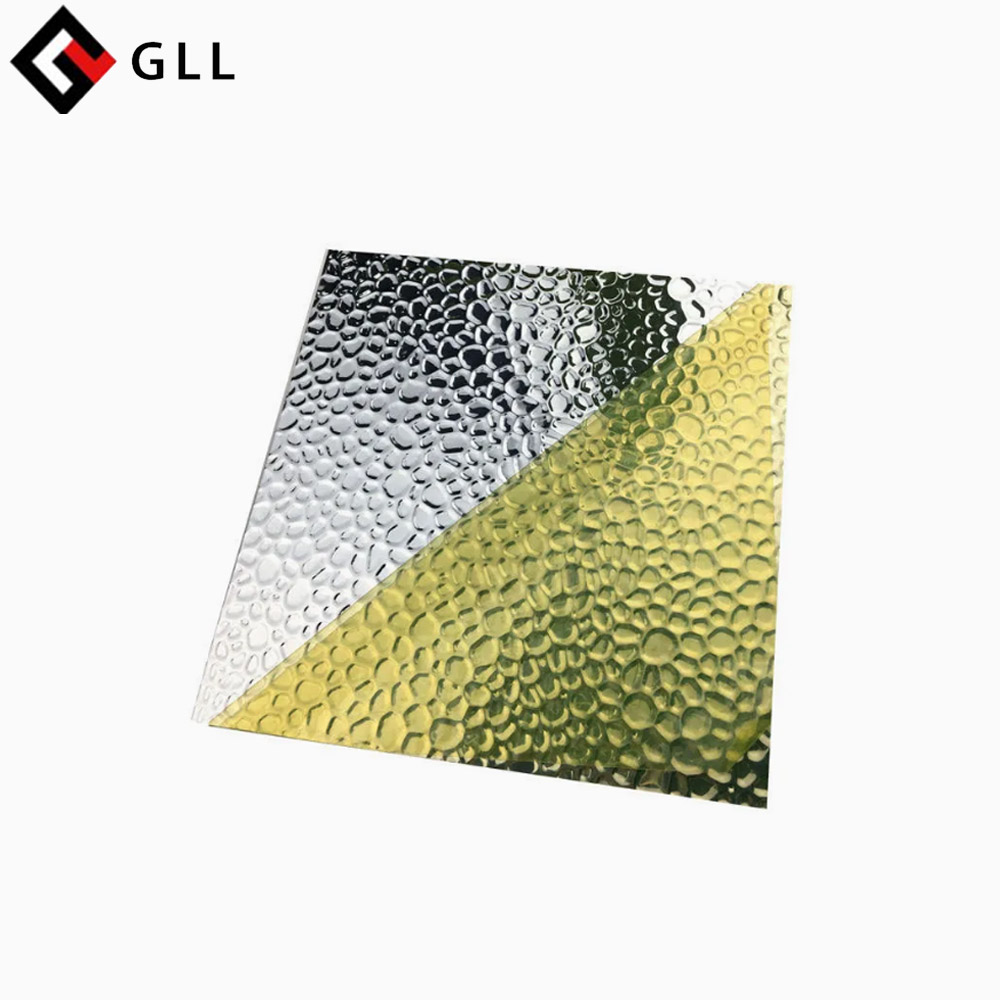

2. Protective Coating System

Anodizing-nano-coating composite treatment forms a 25μm ceramic oxide layer (HV400 Vickers hardness) with exceptional abrasion resistance.

Epoxy-polyurethane dual-component coating system meets ASTM D4060 standards, exhibiting minimal Taber wear (12mg/1000 revolutions).

Field application in a high-traffic port container yard (2,000 daily forklift passes) confirmed maintenance intervals exceeding 5 years, with 62% lower lifecycle cost compared to traditional steel solutions.

Installation & Environmental Adaptability:

The patented mortise-tenon jointing system, secured with M6 stainless steel fasteners, reduces installation time to 33% of conventional methods. Strategically engineered 3-5mm expansion gaps and integrated silicone weather seals ensure dimensional stability across -40°C to 80°C temperature extremes.

Functional Surface Enhancement:

Laser microtexturing technology utilizes ultrashort pulse femtosecond lasers to fabricate periodic microgroove arrays. This innovation achieves :

Coefficient of friction elevation to 0.92 (ASTM D1894 standard).

Self-cleaning capabilities through hydrophobic surface modification.

Reduced contamination adhesion in muddy/oily environments.

Technical Differentiation:

Our GLL solution outperforms conventional products through :

300% longer corrosion resistance in marine atmospheres.

40% higher strength-to-weight ratio vs. mild steel.

75% reduction in maintenance-related downtime.

Compliance with EN 13813 (anti-slip flooring) and ASTM B209 (aluminum plate) standards.