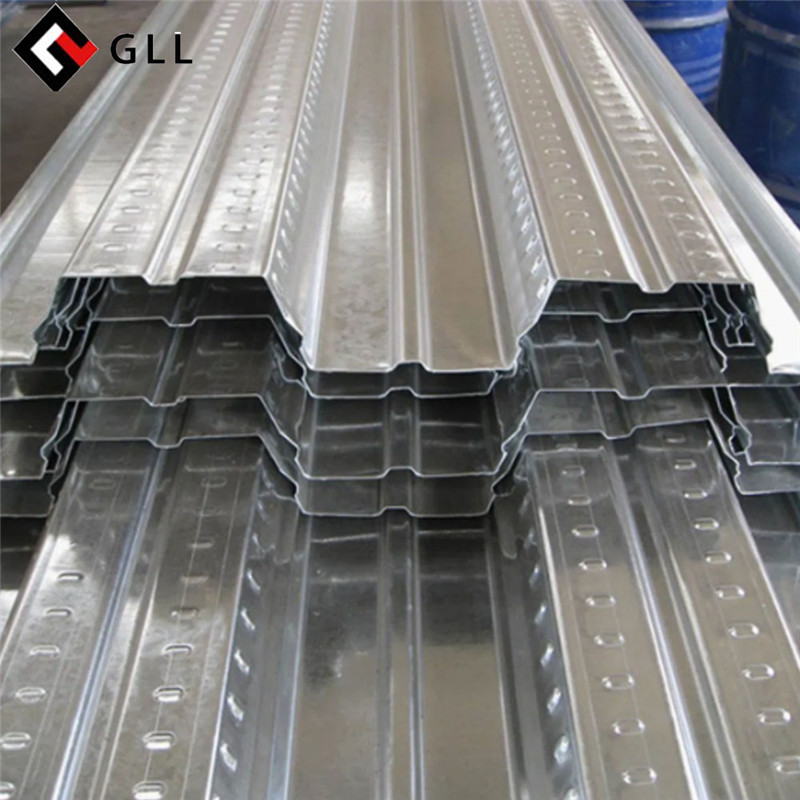

Our GLL galvanized floor deck corrugated steel plate adopts cold rolling/hot rolling process, combined with galvanized surface treatment technology, to achieve multiple performance breakthroughs:

Material strength and lightweight balance: GLL galvanized floor deck corrugated steel plate uses high-strength galvanized steel plate as the base material, and through the corrugated structure design, it reduces the material consumption while ensuring the bearing capacity.

Corrosion resistance and long-term protection : The thickness of our GLL galvanized layer can resist corrosion in harsh environments such as moisture and salt spray. Experimental data shows that GLL galvanized floor deck corrugated steel plate's corrosion resistance is 3-5 times higher than that of ordinary steel plates, and its service life can reach more than 50 years.

Modular design and construction convenience : GLL galvanized sheet supports customized size and opening design, which can be seamlessly connected with the concrete pouring process. The corrugated structure enhances the bonding strength with concrete, reduces the risk of slippage, simplifies the installation process, and shortens the construction period.

Our GLL galvanized floor deck corrugated steel plates have five core advantages

1. Structural efficiency: dual optimization of bearing capacity and economy

The corrugated design increases the moment of inertia of the section, and the bearing capacity is increased by 20%-30% under the same weight;Reduce the amount of steel used and reduce the overall cost, which is in line with the "lightweight" trend of green buildings.

2. Durability: Minimize the cost of the entire life cycle

The galvanized layer provides long-term anti-corrosion protection, and the maintenance cost is reduced by more than 40% compared with traditional materials;Passed ISO 9001 quality certification to ensure product performance consistency.

3. Construction efficiency: modular installation and construction period compression

Standardized size and opening design reduce on-site cutting and welding workload;Synchronize construction with concrete to shorten the construction period by 30%-50%.

4. Fire safety: cast iron-grade fire resistance

Maintains structural stability at 600°C, far exceeding the softening threshold of ordinary steel;Complies with NFPA (National Fire Protection Association) fire protection regulations and is suitable for high-risk areas.

5. Environmental sustainability: low-carbon materials and recycling

Galvanizing process reduces the need for post-maintenance and reduces carbon emissions throughout the life cycle;100% recyclability, in line with LEED certification requirements.