In the application scenarios of solenoid valves, high temperature, high pressure, and highly corrosive media are normal challenges faced by seals. GLL Electromagnetic Valve Seals Manufacturing starts from the source of material research and development and builds a sealing material system covering all working conditions:

Extreme temperature resistant materials: For high temperature scenarios such as aerospace and oil exploration, our GLL have developed fluororubber (FKM) and perfluoroether rubber (FFKM) composite materials that can work stably in the range of -40℃ to 250℃ to ensure that the sealing performance is not attenuated due to drastic temperature changes.

Chemically inert materials: In high-clean fields such as semiconductor manufacturing and pharmaceutical production, GLL uses PTFE (polytetrafluoroethylene) substrates and nano-level modification technology to resist acid, alkali, and organic solvent erosion and avoid the risk of media contamination.

Low friction and self-lubricating materials: Through surface microstructure treatment and molecular-level lubricating additives, the friction coefficient of our seals is reduced by 30%, which significantly reduces the energy consumption of solenoid valve operation and extends the life of the equipment.

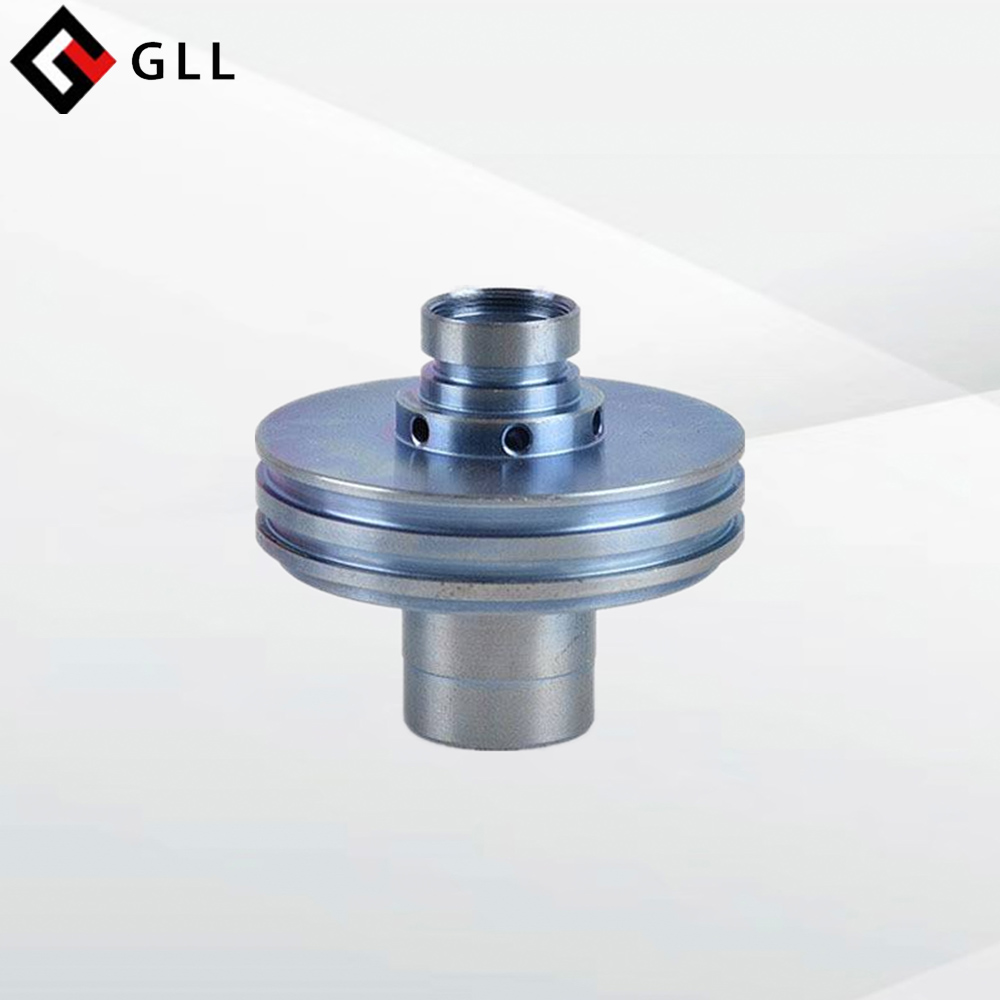

Traditional seals often leak or wear due to design defects. GLL Manufacturing introduces a dynamic seal simulation platform. Through fluid mechanics analysis and real-time simulation, it creates a precise structure that is suitable for various solenoid valves:

Double-layer sealing system: The main sealing layer bears high-pressure sealing, and the auxiliary sealing layer compensates for micro-gaps through elastic deformation, which can maintain 100% sealing even under pressure fluctuations.

Adaptive lip design: The sealing lip adopts a gradual taper and flexible reinforcement rib structure, which quickly responds to pressure changes at the moment of opening and closing of the solenoid valve to avoid medium backflow or valve core jamming.

Modular adaptation solution: It provides standard interfaces and customized sizes, and is compatible with mainstream brand solenoid valves. Customers can directly replace them without modifying the equipment, reducing upgrade costs.

FAQ

Q1: How to choose the appropriate sealing material?

A: Select the material according to the medium type (such as hydraulic oil, chemical solvent) and temperature range. FKM is suitable for high-temperature oils, and PTFE is suitable for highly corrosive media.

Q2: What should be paid attention to during installation?

A:Should make sure the sealing surface is clean and free of scratches, and avoid deformation caused by over-tightening. It is recommended to use special installation tools.

Q3: Does the product support customization?

A: Customized services for non-standard sizes and special media adaptation are supported, and working pressure, temperature and other parameters must be provided.

Q4: Is additional maintenance required during the life cycle?

A: No regular lubrication is required. It is recommended to check the wear of the sealing surface after every 500,000 cycles.