Our GLL Aluminum I-beam Scaffolding uses high-strength aluminum alloy such as 6063, 6061, 6005 and other grades as the core material, combined with T4, T5, T6 heat treatment process to ensure that the product has excellent mechanical properties and corrosion resistance. GLL Aluminum I-beam Scaffolding is widely used in construction, industrial and commercial projects.

The naturally formed aluminum oxide protective layer on the surface of aluminum alloy gives GLL I beams extremely strong corrosion resistance. In the salt spray test, GLL I Beam corrosion resistance reaches more than 1,000 hours according to the ASTM B117 standard, far exceeding the 200 hours of ordinary carbon steel. In the container terminal renovation project, GLL aluminum scaffolding has been used continuously for 5 years in a marine climate without rust, and the maintenance cost has been reduced by 80%.

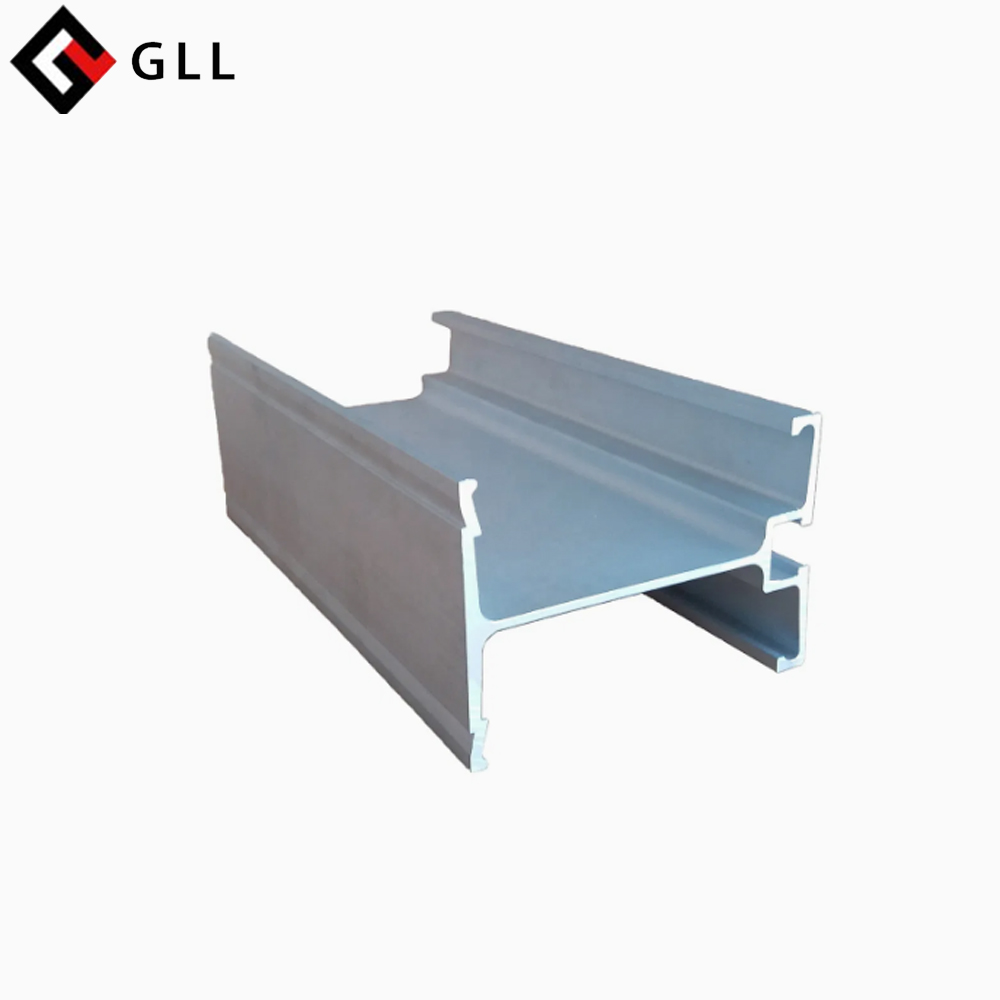

GLL Aluminum I Beam adopts the European standard I-section (such as 180×90mm), and the cold drawing process ensures the dimensional accuracy of ±0.2mm. The modular connection system supports horizontal, vertical and diagonal combinations, and can quickly build arc-shaped, spiral-shaped and other special-shaped structures. In the building construction in London, GLL used the flexible design of the I beam to complete the construction of a 35-meter-diameter circular support platform in just 72 hours, with an error control within 3mm.

GLL Aluminum I Beam has three core advantages

1. Balance between light weight and high strength

Material innovation: 6063-T6 aluminum alloy is used, the density is only 1/3 of steel, but the bending strength is 310MPa, which exceeds the traditional steel scaffolding.

Structural design: I-section optimized design, upper and lower flange width ratio of 3:1, significantly improve torsional rigidity, reduce material consumption.

2. Breakthrough in corrosion resistance

Surface treatment: Anodized layer thickness ≥ 15μm, no corrosion in salt spray test for more than 1000 hours, suitable for coastal and chemical environments.

Coating process: Powder coating uses Akzo Nobel Interpon series, UV anti-aging level reaches 5, outdoor service life exceeds 15 years.

3. Improved construction efficiency

Modular design: The weight of a single beam is only 9.5-20.5kg, which increases manual handling efficiency by 40% and reduces reliance on lifting equipment.

Quick connection system: Patented wedge-shaped joint, which can be locked in 3 seconds, increases installation speed by 60%.

FAQ

Q1: Is aluminum scaffolding suitable for heavy machinery construction? A: After testing, a single 6063-T6 material can bear up to 2.0 tons and can support concrete pouring equipment. It is recommended to use it with our GLL patented support system to ensure dynamic load safety. Q2: Performance in extreme temperature environments? A: Engineered for extreme climates, GLL 6061-T6 aluminum alloy operates reliably across a temperature spectrum of -40°C to 80°C. Q3: Maintenance cost compared with traditional steel products? A: The surface treatment life is extended by 3 times, and the maintenance frequency is reduced by 70%. Calculated over a 5-year cycle, the comprehensive cost is reduced by 28% (including replacement and anti-corrosion treatment csts).