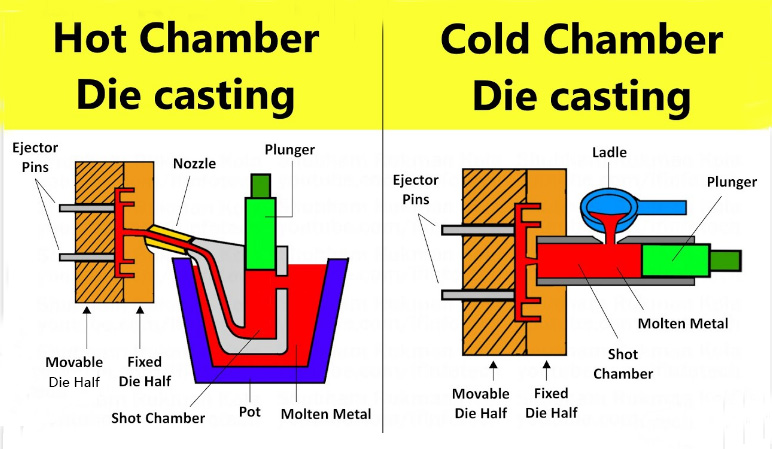

Hot Chamber Die Casting and Cold Chamber Die Casting are two most common ways in Die Casting process. The picture above depicts a simple process of each die casting method, and we can see from the picture that the equipment on the left are quietly the same.

Hot Chamber Die Casting

Hot Chamber Die Casting is particularly more popular than Cold Chamber Die Casting owing to its high degree of automation, less material loss, and high production efficiency. The shot chamber is submerged in liquid molten metal, which are contained by a Pot. Then the molten metal is injected through the Nozzle to the die under high speed and high pressure that is created by a hydraulic or pneumatic piston. After the injection of molten metal, the molten metal fills the cavity between movable die half and fixed die half to form into the desired shape. When the molten metal solidifies, the ejector pins push the casting out. The process is usually faster than Cold Chamber Die Casting Process but it requires the metals with lower melting points such as zinc, lead, and magnesium. For materials like Aluminum and Aluminum Alloy, their melting points are relatively higher and they have the risks of eroding the equipment.

Cold Chamber Die Casting

This process is to make molten metal ladled manually or ladled by a machine into the chamber from an eternal furnace. The force promoted by the plunger push the molten metal to enter the cavity between movable die half and fixed die half to form into the desired shape. And the later process is the same as the Hot Chamber Die Casting Process. But this method is probably more suitable for materials with higher melting points, such as Aluminum, Aluminum Alloy and Copper. Actually it would be slower than Hot Chamber Die Casting Process because it would take time in the molten metal transferring process.

Conclusion

Both Hot Chamber Die Casting and Cold Chamber Die Casting are widely used in Casting Industry. Both of them can offer high accuracy and precision. In addition, both processes are relatively fast and cost-effective. The actual choice between them depends on the materials and application requirements.

GLL Offers Exclusive Hot and Cold Chamber Die Casting Service

In conclusion, die casting is a precise and efficient manufacturing process that enables the production of complex components with excellent mechanical properties. Its ability to create intricate shapes, high dimensional accuracy, and the versatility of aluminum alloys make it a popular choice in numerous industries. As a qualified manufacturer and supplier with experiences of more than 30 years, GLL is devoted to provide customers with the desired Casting Parts. You can contact us to have a look.