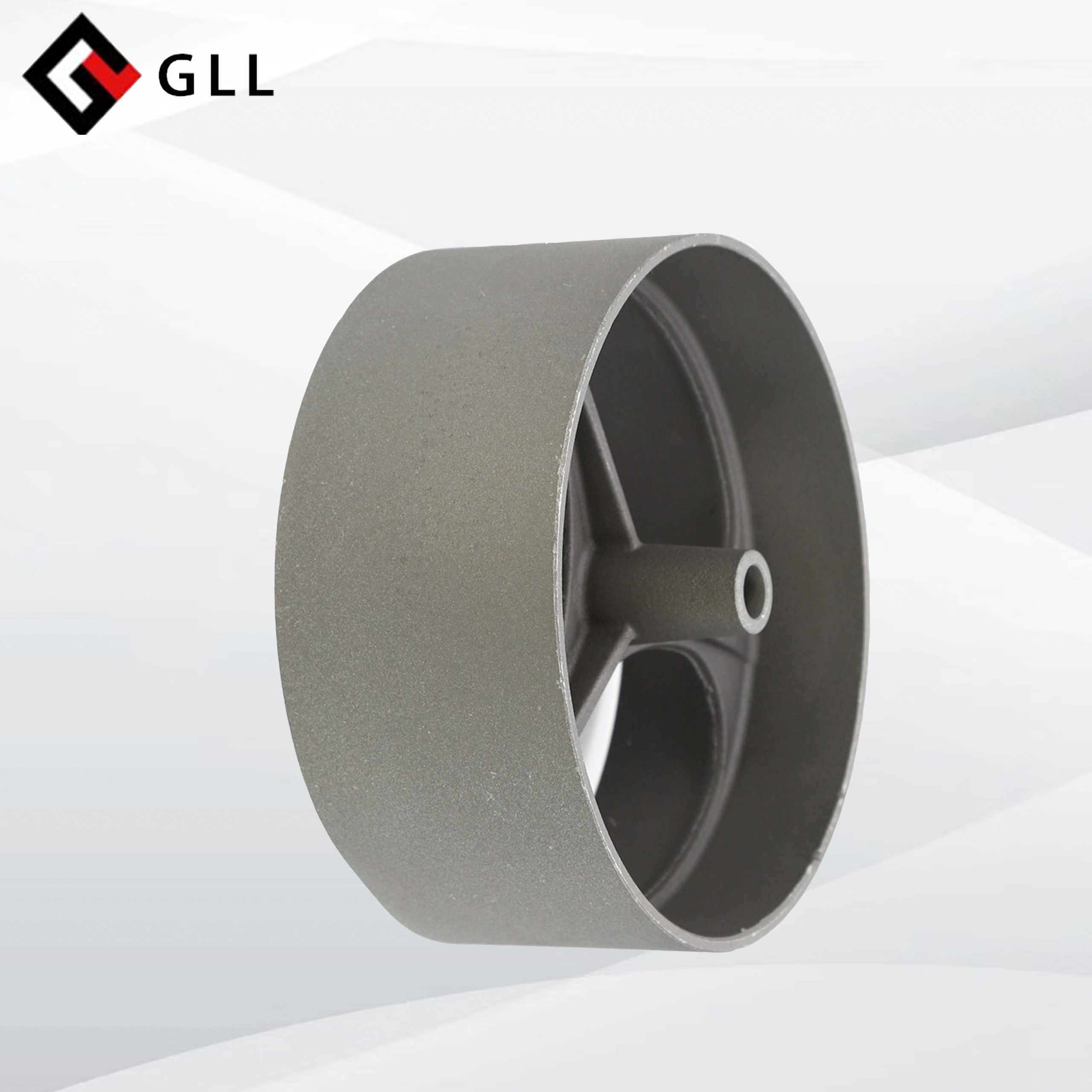

In the manufacturing process of aluminum alloy wheels, our GLL employs advanced casting technology alongside strict quality control standards. To enhance its strength, carbon, magnesium powder, and other metallic elements are added. After impurities and hydrogen are removed, the refined molten aluminum is injected into a mold crafted from high-strength steel.the molten aluminum is injected into a mold made of high-strength steel. The mold is precisely designed to ensure the style and precision of the wheel. After casting, the wheel needs to go through a long solidification and cooling process, and then further processed by heat treatment process, including heating, quenching and continuous heating to lock the strength and stability of the metal. Finally, precision machining is carried out by computer lathe to ensure that the size and shape of the wheel meet the design requirements, and strict airtightness test is passed to ensure product quality. The core advantages of Our GLL aluminum alloy wheels High-quality raw materials : Our GLL aluminum alloy wheels offer superior corrosion resistance and durability compared to conventional steel wheels. Made from high-purity aluminum alloy materials that undergo thorough screening and processing, these wheels are designed to last. Furthermore, their lighter weight, in contrast to traditional steel wheels, helps improve fuel efficiency and enhances vehicle handling. Innovative design and technology: Our GLL is committed to designing highly personalized and sporty wheels. Its wheel styles are rich and varied, from classic five-spoke and ten-spoke designs to more complex multi-spoke designs, showing the charm of exquisiteness and luxury. At the same time, GLL continues to introduce advanced manufacturing technologies, such as precision casting and forging technology, to ensure that each wheel can find a perfect balance between strength and weight. Lightweight and performance: The standout feature of aluminum alloy wheels is their lightweight design. GLL leverages innovative structural engineering to reduce wheel weight while preserving strength, improving the vehicle’s acceleration, braking, and handling performance. Additionally, the lighter weight helps reduce fuel consumption and boost fuel efficiency, aligning perfectly with today's focus on environmental sustainability and energy efficiency.