Product Description

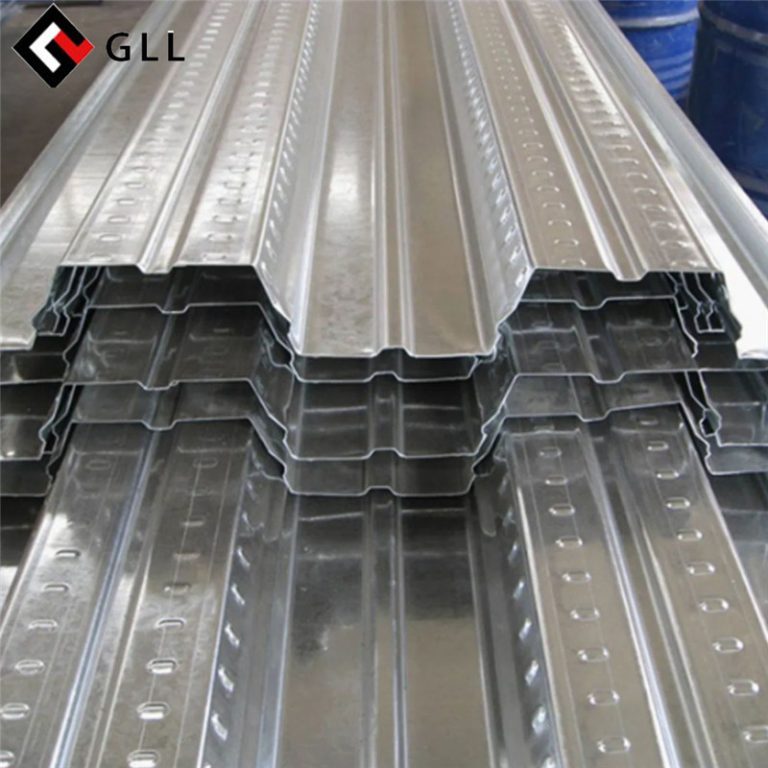

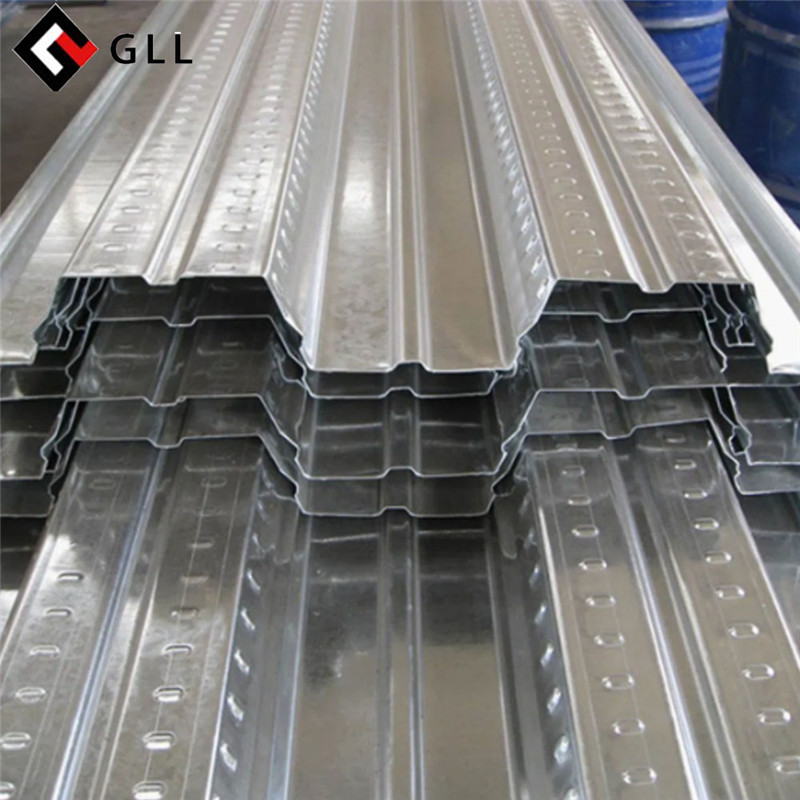

GLL galvanized floor decking sheet is a cold-formed steel product made from high-quality hot-dip galvanized steel coils. It features a corrugated profile design that enhances load-bearing capacity and ensures strong bonding with concrete. Widely used in multi-story buildings, commercial centers, and industrial structures, this decking sheet provides a safe, efficient, and cost-effective solution for floor slab construction.

Key Features

High Load Capacity: Corrugated design provides excellent structural strength and bending resistance.

Durable Material: Made of premium hot-dip galvanized steel for superior corrosion resistance and long service life.

Fast Installation: Easily welded or fastened to steel beams, reducing construction time and labor cost.

Customizable Profiles: Available in various thicknesses, heights, and rib designs (e.g., YX51-240-720, YX75-200-600) to meet specific project requirements.

Eco-Friendly: Reduces the need for traditional formwork; recyclable steel contributes to green building practices.

Applications

Multi-story steel building floor systems

High-rise concrete composite floor slabs

Underground garages and basement roof slabs

Bridge platforms and steel structure decking

Detailed photos

Packaging

Standard Packaging: Sheets are bundled with steel straps and wrapped in waterproof kraft paper or plastic film for protection against moisture and corrosion during transit.

Edge Protection: Reinforced steel or wooden edge protectors are used to prevent damage during loading and unloading.

Secure Strapping: Each bundle is fastened with multiple steel bands (horizontal and vertical) to ensure tight and safe packaging.

Company Profile

GLL specializes in manufacturing high-quality die-cast parts for a broad range of industries, with a strong emphasis on OEM and ODM solutions. Our product offerings include:

Our advantage

As an extension of our manufacturing groups, our foundry is dedicated to understanding our customers’ businesses and developing the necessary capabilities to meet their needs for commodities we support.

Copyright © 2023·GLL CASTINGAll rights reserved.