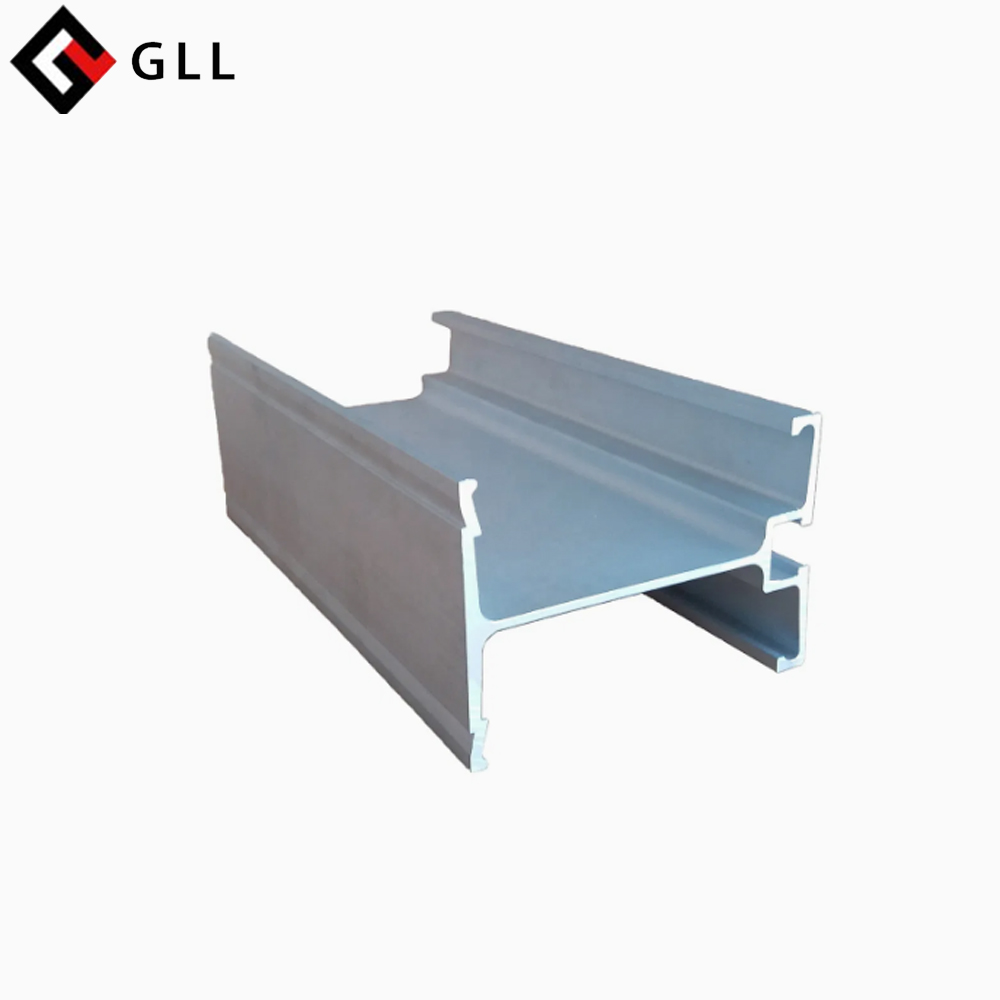

Product Description

GLL Aluminum I Beam for scaffolding is a high-strength, lightweight structural component designed for temporary and permanent scaffolding systems. Made from premium-grade aluminum alloy (typically 6061-T6 or 6082-T6), it offers excellent corrosion resistance, durability, and ease of handling—ideal for use in construction, maintenance, and industrial access applications.

Key Features

Lightweight and Strong:

Aluminum I-beams offer an excellent strength-to-weight ratio, reducing labor intensity and transportation costs while maintaining structural integrity.

Corrosion Resistant:

The anodized or natural finish aluminum surface resists rust and weathering, suitable for both indoor and outdoor use.

High Load Capacity:

Engineered for heavy-duty applications, capable of supporting significant loads across long spans.

Precision Design:

Manufactured to tight tolerances for a perfect fit with scaffold frames, decks, and coupling systems.

Versatile Application:

Ideal for suspended scaffolding, bridge decking, working platforms, and temporary support structures.

Detailed photos

Applications

Suspended scaffolding platforms

Modular scaffolding systems

Walkways and decking structures

Temporary load-bearing bridges

Maintenance access in industrial sites

Packaging and shipping

1. Carton Box Packing: Cost-effective and allows for higher loading capacity, though it may pose challenges for loading and unloading.

2. Wooden or Steel Pallets Packing: Easy loading and unloading.

3. Customized Packing: Options selected based on clients’ requirements

4. Shipping: Better to choose sea shipment, if urgent demand can choose Air shipment

Company Profile

GLL is a leading manufacturer in China, offering comprehensive one-stop solutions that encompass die casting, gravity casting, sand casting, investment casting, CNC machining, surface treatment, and assembly. As a professional OEM/ODM company, we combine extensive production expertise with the ability to design or recommend products tailored to meet our customers’ unique needs. Our global customer base spans North America, Europe, South America, Asia, Oceania, and Africa, reflecting our commitment to serving diverse markets worldwide.

Our advantage

As an extension of our manufacturing groups, our foundry is dedicated to understanding our customers’ businesses and developing the necessary capabilities to meet their needs for commodities we support.

Copyright © 2023·GLL CASTINGAll rights reserved.