Aluminum is a lightweight, silver-white metal that is widely used in various industries due to its unique properties. It is the third most abundant element in the Earth’s crust, making up about 8% of the planet’s weight. Aluminum is highly malleable and ductile, which means it can be easily shaped into different forms without breaking or cracking. It is also corrosion-resistant, non-toxic, and has excellent thermal and electrical conductivity. These properties make it an ideal material for casting, which is the process of creating metal objects by pouring molten metal into a mold.

Aluminum casting is a popular manufacturing method used in various industries such as aerospace, automotive, construction, and consumer goods. The process involves melting aluminum in a furnace and pouring it into a mold, which is then cooled and removed to reveal the finished product. Aluminum casting allows for complex shapes and designs to be created with high precision and accuracy.

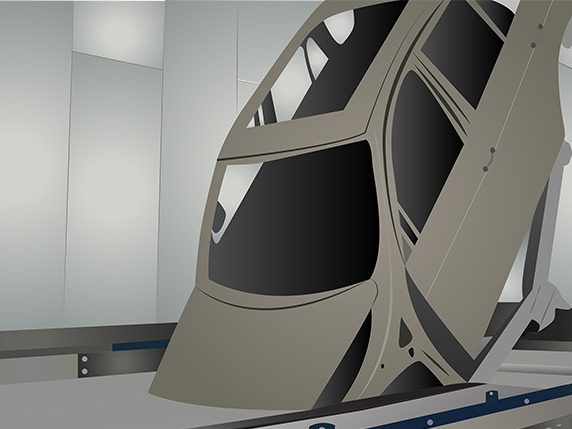

One of the most common applications of aluminum casting is in the production of automotive parts. Aluminum is widely used in the automotive industry due to its lightweight and high strength-to-weight ratio. It is used to make engine blocks, cylinder heads, wheels, and other components that require high strength and durability. Aluminum casting also allows for the creation of intricate designs and shapes that cannot be achieved with other materials.

Another industry that heavily relies on aluminum casting is aerospace. Aluminum is used in the construction of aircraft and spacecraft due to its lightweight and high strength-to-weight ratio. It is used to make structural components, such as wings, fuselage, and landing gear. Aluminum casting also allows for the creation of complex shapes and designs that are necessary for aerospace applications.

In the construction industry, aluminum casting is used to create decorative and functional elements such as balustrades, railings, and columns. Aluminum is an ideal material for these applications due to its corrosion resistance and low maintenance requirements. Aluminum casting allows for the creation of intricate designs and shapes that enhance the aesthetic appeal of buildings.

In my mind, aluminum is a versatile metal with diverse applications in casting. Its unique properties make it an ideal material for creating complex shapes and designs with high precision and accuracy. Aluminum casting is widely used in various industries such as automotive, aerospace, and construction, where lightweight and high strength-to-weight ratio are essential. As technology advances, the use of aluminum casting is expected to increase, and new applications will continue to emerge.