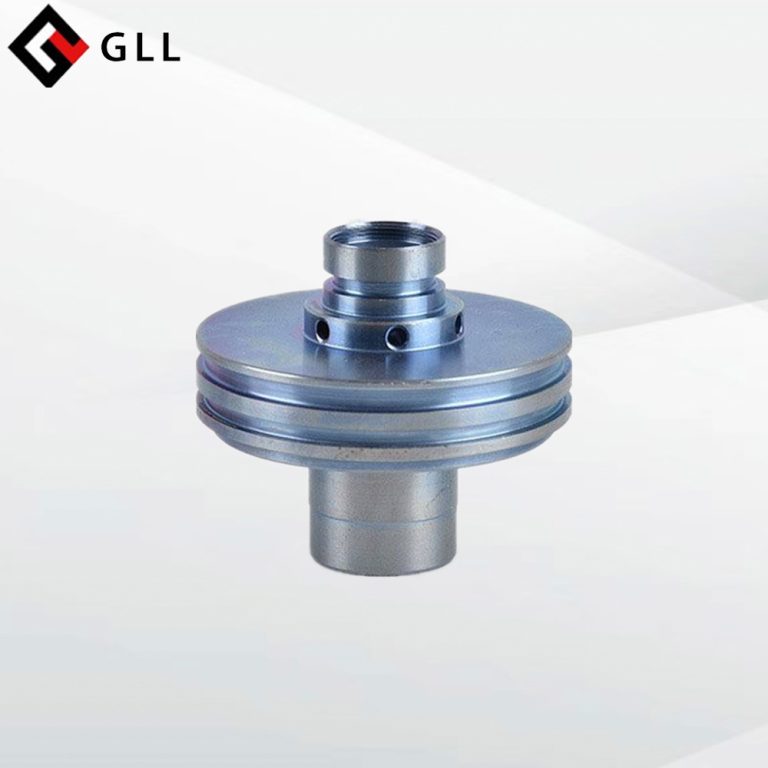

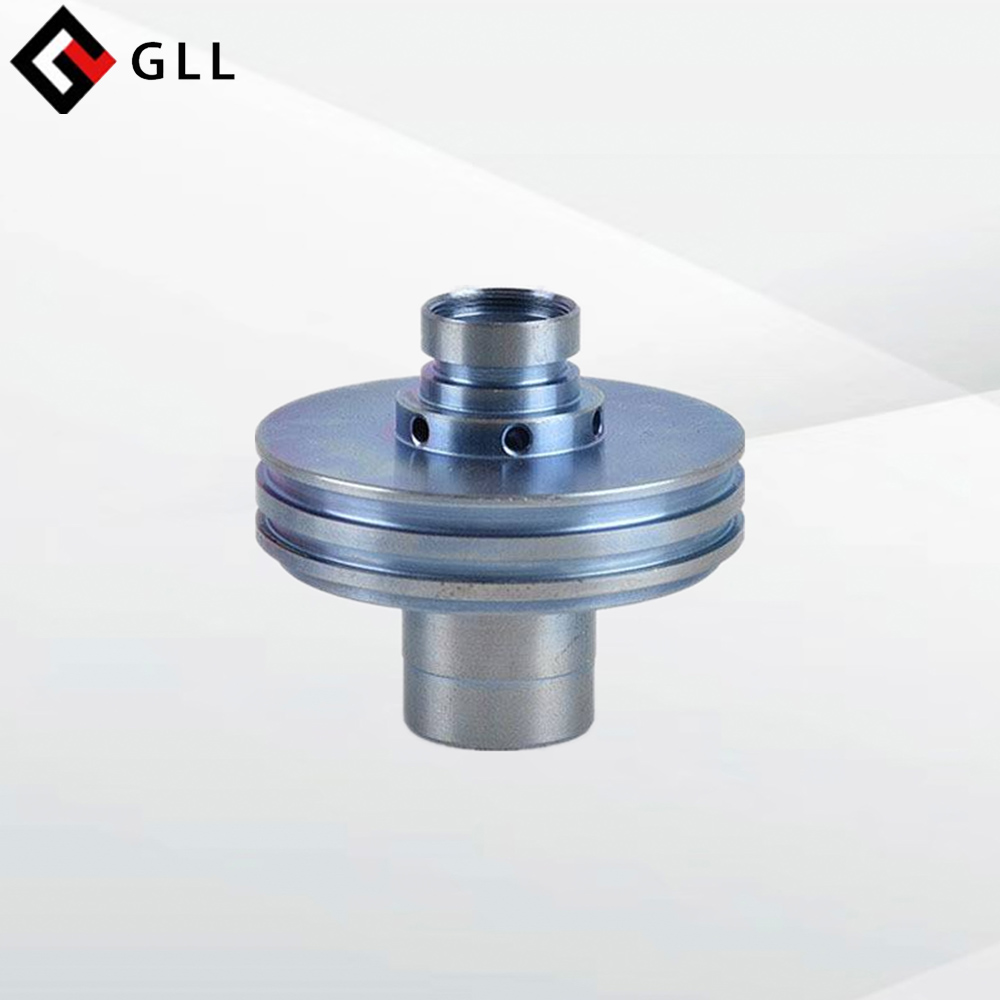

Product Description

GLL series solenoid valve seals provide high-precision machining solutions, covering the customized processing of key structural parts such as valve core, valve seat, sealing guide sleeve and housing. All sealing components are made of high-performance materials such as stainless steel, brass, aluminum alloy and PTFE. Through CNC turning and milling, precision inner hole machining and surface polishing processes, the sealing surface roughness can be within Ra 0.2μm, and the tolerance control accuracy can reach ±0.005mm, meeting the strict requirements of solenoid valves for sealing, coaxiality and corrosion resistance.

Key Features

High-Precision Sealing:Manufactured using premium materials such as PTFE, FKM, and EPDM, offering excellent resistance to chemicals, high temperatures, and pressure — ensuring long-term, leak-free operation.

Wide Media Compatibility:Suitable for water, oil, steam, and compressed air. Select models support fluids with viscosities below 20 cSt and can operate in temperature ranges from –5 °C to 180 °C.

Precision-Machined Valve Seats & Diaphragms:Engineered for fast actuation and optimal sealing performance, available in both normally closed (N/C) and normally open (N/O) configurations.

High Pressure Tolerance:Normally closed models withstand up to 16 bar; normally open versions up to 8 bar — meeting diverse fluid control requirements.

Electrical Control Compatibility:Designed for 12 V/DC, 24 V/DC, or 110–230 V/AC operations, offering flexibility for integration into standard industrial power systems.

Ingress Protection:Most models comply with IP54 protection standards, ensuring reliable operation in dust- and moisture-prone environments.

Detailed photos

Packaging and shipping

1. Carton Box Packing: Cost-effective and allows for higher loading capacity, though it may pose challenges for loading and unloading.

2. Wooden or Steel Pallets Packing: Easy loading and unloading.

3. Customized Packing: Options selected based on clients’ requirements

4. Shipping: Better to choose sea shipment, if urgent demand can choose Air shipment

Company Profile

GLL is a leading manufacturer in China, offering comprehensive one-stop solutions that encompass die casting, gravity casting, sand casting, investment casting, CNC machining, surface treatment, and assembly. As a professional OEM/ODM company, we combine extensive production expertise with the ability to design or recommend products tailored to meet our customers’ unique needs. Our global customer base spans North America, Europe, South America, Asia, Oceania, and Africa, reflecting our commitment to serving diverse markets worldwide.

Our advantage

As an extension of our manufacturing groups, our foundry is dedicated to understanding our customers’ businesses and developing the necessary capabilities to meet their needs for commodities we support.

Copyright © 2023·GLL CASTINGAll rights reserved.